Built for material quality, clean construction, and repeatable workmanship.

Leather and PU accessories rely on disciplined cutting, stitching, and finishing processes. Edge quality, hardware integration, and material consistency determine durability and perceived value — especially as production scales.

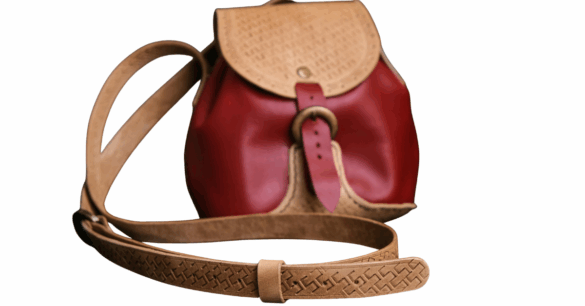

This category covers both genuine leather and PU-based accessories across fashion and functional use cases.

What Falls Under Leather & PU Accessories Manufacturing

This category includes accessories constructed primarily from leather or synthetic leather materials.

Common product types include:

Material selection, cutting accuracy, and finishing standards are critical for consistency and longevity.

How Leather & PU Accessories Are Manufactured

Leather and PU production follows a multi-step assembly-driven process:

Material Sourcing & Inspection

Hides or PU sheets are evaluated for thickness, texture, and defects.

Cutting & Shaping

Materials are cut using dies or CNC cutting to ensure accuracy.

Edge Finishing & Reinforcement

Edges are painted, burnished, or sealed for durability and appearance.

Stitching & Assembly

Components are stitched and assembled, often with hardware integration.

Final Finishing & Inspection

Products are cleaned, inspected, and packed for shipment.

Each step affects wear, comfort, and long-term durability.

Key Manufacturing Decisions Founders Need to Make

Leather and PU accessories require careful tradeoff decisions early.

Why it matters:

Material choice impacts durability, aging, cost, and customer expectations.

What to consider:

- Genuine leather: natural variation, patina over time, higher cost

- PU: consistent appearance, lower cost, less breathable

- Target price point and product positioning

Common pitfalls:

Marketing PU as leather-like without managing wear and longevity expectations.

Why it matters:

Thickness determines structure, flexibility, and how leather performs in assembly.

What to consider:

- Target thickness ranges by component

- Reinforcement or backing layers

- Flex points and stress areas

Common pitfalls:

Choosing leather that’s too thin, leading to stretching or premature wear.

Why it matters:

Edges are one of the first places wear becomes visible.

What to consider:

- Raw cut vs painted edges

- Folded or turned edges for durability

- Color matching and adhesion

Common pitfalls:

Skipping edge finishing specs and seeing fraying or cracking after use.

Why it matters:

Stitching affects both strength and perceived craftsmanship.

What to consider:

- Stitches per inch (SPI) standards

- Thread material and thickness

- Stress points requiring reinforcement

Common pitfalls:

Under-specifying stitch density, resulting in loose seams or uneven spacing.

Why it matters:

Leather must work seamlessly with metal components and fasteners.

What to consider:

- Hole tolerances for rivets and screws

- Pull strength and tear resistance

- Interaction with plated or coated hardware

Common pitfalls:

Using hardware that tears through leather under normal use.

Why it matters:

Leather cutting produces waste — yield planning affects unit cost.

What to consider:

- Hide size and usable area

- Natural defect rates

- Minimum order quantities tied to cutting efficiency

Common pitfalls:

Ignoring yield loss when pricing or planning production volumes.

Early clarity reduces defects, waste, and rework.

Common Challenges in Leather & PU Production

This category often fails on execution rather than design.

Common risks include:

- Inconsistent leather grain or texture

- Fraying or cracking edges

- Weak stitching or skipped seams

- Poor hardware attachment

- Material waste due to poor cutting layouts

- Inconsistent output across batches

These issues are preventable with proper oversight and supplier vetting.

How Sourcify Supports Leather & PU Manufacturing

Sourcify helps brands produce leather and PU accessories that meet durability and quality expectations.

We support this category by:

- Vetting factories for leather handling and stitching expertise

- Reviewing material sourcing and grading standards

- Managing samples and construction revisions

- Aligning hardware and material suppliers

- Establishing QC standards for finish and assembly

- Planning backup factories to reduce risk

Our focus is craftsmanship that scales — not shortcuts that fail later.

Who This Is Best For

Leather and PU accessories manufacturing through Sourcify is a strong fit for:

- Brands producing leather-based accessories

- Teams improving construction quality

- Founders scaling production volumes

- Brands experiencing durability issues

- Collections where materials define brand perception

Ready to Get Started?

If you’re sourcing leather or PU accessories and want consistent quality at scale, we can help.