Built for secure settings, repeatable quality, and production consistency.

Stone-set jewelry introduces an added layer of complexity to metal production. Beyond casting and finishing, factories must execute reliable setting techniques that protect stones, maintain alignment, and hold up through wear — especially at scale.

This category covers decorative stones that do not require regulatory sourcing or certification.

What Falls Under Stone-Set Jewelry Manufacturing

This category includes metal jewelry designs that incorporate decorative stones or inserts.

Common product types include:

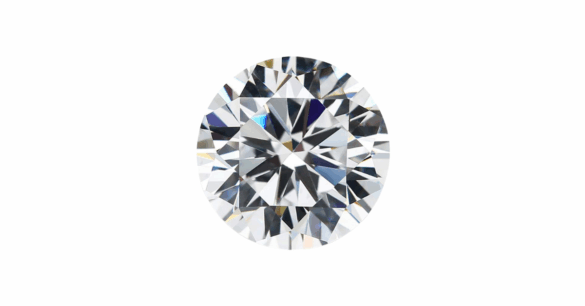

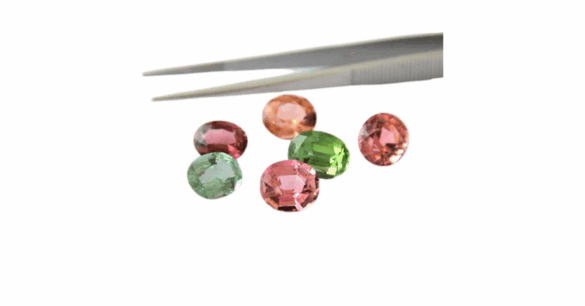

Typical stone types include:

These designs rely on precise setting work to ensure durability and visual consistency.

How Stone-Set Jewelry Is Manufactured

Stone-set jewelry follows the metal production process with additional steps for setting and inspection:

Design & CAD Development

Stone size, placement, and setting type are defined at the design stage.

Casting or Machining of Metal Components

Metal parts are produced with setting tolerances built in.

Pre-Finishing & Preparation

Pieces are cleaned and prepared prior to stone setting.

Stone Setting

Stones are secured using prong, bezel, channel, pavé, or glue-assisted techniques depending on design.

Final Finishing & Polishing

Finishing is completed without loosening or damaging stones.

Quality Control & Pull Testing

Finished pieces are inspected for alignment, security, and fallout risk.

Stone setting quality directly impacts customer experience, returns, and long-term brand perception.

Key Manufacturing Decisions Founders Need to Make

Stone-set designs require clear decisions early to avoid downstream issues.

Why it matters:

Even small size variations can cause setting issues, uneven spacing, or increased fallout.

What to consider:

- Natural vs lab-grown stones

- Cut consistency and calibration

- Acceptable size variance per stone

Common pitfalls:

Using poorly calibrated stones that slow setting time or cause inconsistent aesthetics.

Why it matters:

Each setting style balances security, labor cost, and visual impact differently.

What to consider:

- Prong: flexible and cost-effective, but higher snag risk

- Bezel: secure and durable, higher metal and labor cost

- Pavé: visually striking, requires precise tolerances and QC

- Channel: clean look, strong protection, higher precision requirements

Common pitfalls:

Choosing a setting style without accounting for wear, repairability, or production yield.

Why it matters:

The setting method affects speed, consistency, and labor cost.

What to consider:

- Hand-setting for high-end or irregular stones

- Machine-assisted setting for calibrated stones and scale

- Skill variability between setters

Common pitfalls:

Expecting machine-level consistency from fully hand-set production without added QC.

Why it matters:

Adhesives can support stones — but shouldn’t replace proper setting.

What to consider:

- Glue as a temporary aid vs permanent solution

- Heat and chemical exposure during wear

- Long-term durability expectations

Common pitfalls:

Over-reliance on glue leading to premature stone loss and customer complaints.

Why it matters:

No production run is perfect — defining acceptable fallout upfront prevents disputes later.

What to consider:

- Target fallout percentage per batch

- Rework vs rejection thresholds

- Responsibility for replacements

Common pitfalls:

Failing to define fallout expectations until after defects appear.

Why it matters:

Stone-related defects are easier and cheaper to catch early.

What to consider:

- In-process inspections during setting

- Final inspection under magnification

- Drop, wear, or vibration testing (if applicable)

Common pitfalls:

Relying only on final inspection instead of multiple QC checkpoints.

These decisions affect cost, production speed, and long-term durability.

Common Challenges in Stone-Set Jewelry Production

Stone-set jewelry is especially sensitive to execution errors.

Common risks include:

- Loose stones or fallout after finishing

- Misaligned or uneven stone placement

- Inconsistent stone color across batches

- Damage during polishing or plating

- Factories lacking skilled setting labor

- Rushed production reducing QC effectiveness

Most issues stem from mismatched factory capabilities rather than design flaws.

How Sourcify Supports Stone-Set Jewelry Manufacturing

Sourcify helps brands navigate the added complexity of stone-set production.

We support this category by:

- Matching you with factories experienced in stone-setting

- Reviewing designs for setting feasibility and durability

- Managing sampling and setting revisions

- Establishing realistic fallout and QC expectations

- Ensuring alignment between metal, plating, and setting teams

- Planning backups to reduce production risk

Our role is to ensure stones stay secure — not just during inspection, but after customers start wearing them.

Who This Is Best For

Stone-set jewelry manufacturing through Sourcify is a strong fit for:

- Brands offering CZ or semi-precious stone designs

- Founders scaling beyond small-batch hand setting

- Teams experiencing stone fallout or inconsistency

- Brands seeking repeatable quality across SKUs

- Collections where finish quality drives perceived value

Ready to Get Started?

If you’re producing stone-set jewelry and want consistent quality at scale, we can help.