Built for consistency, durability, and precise tolerances at scale.

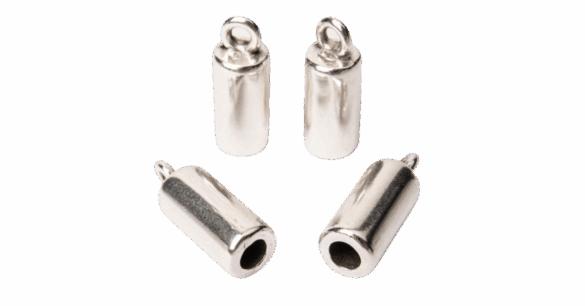

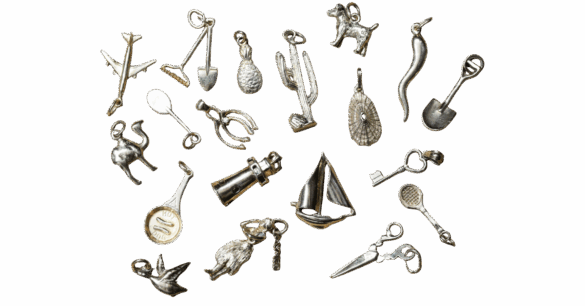

Chains and jewelry components are the backbone of finished pieces. From chain links to clasps and connectors, these parts must meet tight tolerance standards to ensure proper fit, strength, and long-term wear — especially when produced at volume.

What Falls Under Chains, Findings & Components

This category includes metal components designed for assembly into finished jewelry and accessories.

Common product types include:

Materials typically include brass, stainless steel, sterling silver, and plated base metals, depending on strength, weight, and finish requirements.

How Chains & Components Are Manufactured

While designs vary, most chains and findings follow a precision-driven production process:

Wire Drawing or Sheet Preparation

Metal wire or sheet is produced to exact gauges and tolerances.

Link Forming or Component Stamping

Chains are formed link-by-link or via automated machinery; findings are stamped or machined.

Cutting, Assembly, and Soldering

Links are cut, assembled, and soldered or welded where required for strength.

Surface Treatment & Plating

Components are polished, plated, or coated to achieve durability and finish consistency.

Quality Control & Load Testing

Finished parts are inspected for size accuracy, closure strength, and finish quality.

Because these components are used repeatedly across SKUs, even small inconsistencies can compound into larger production issues.

Key Manufacturing Decisions Founders Need to Make

Small components still require big decisions early.

Why it matters:

Different chain styles (cable, curb, box, rope) behave very differently under tension and wear.

What to consider:

Open vs closed links

Handmade vs machine-made chains

Visual density vs strength

Common pitfalls:

Choosing a delicate-looking chain that stretches, snags, or fails during normal wear.

Why it matters:

Wire gauge directly affects durability, weight, and cost.

What to consider:

Thinner wire = lower cost, higher risk of deformation

Thicker wire = stronger, heavier, higher material cost

Common pitfalls:

Optimizing for aesthetics without accounting for long-term wear or customer handling.

Why it matters:

Small dimensional variations can break assembly, clasps, or stone settings.

What to consider:

How tight parts need to fit together

Whether components are hand-assembled or automated

Acceptable variance between batches

Common pitfalls:

Loose tolerances that cause inconsistent assembly or high rejection rates.

Why it matters:

Soldering impacts strength, labor cost, and visual finish.

What to consider:

Soldered links for strength and longevity

Unsoldered links for speed and lower cost

Common pitfalls:

Skipping soldering to save cost — then dealing with breakage and returns later.

Why it matters:

Plating quality determines wear resistance, color longevity, and customer satisfaction.

What to consider:

Micron thickness requirements

Base metal preparation

Adhesion testing standards

Common pitfalls:

Thin plating that wears through quickly or flakes due to poor surface prep.

Why it matters:

Minimums and batch sizing affect pricing, consistency, and reorder flexibility.

What to consider:

Minimum order quantities per SKU

Batch-to-batch color and weight consistency

Reorder lead times

Common pitfalls:

Agreeing to low MOQs that compromise quality control or consistency.

These decisions directly impact wear performance, assembly efficiency, and customer satisfaction.

Common Challenges in Chains & Components Production

This category is often underestimated because of its size — but it’s highly technical.

Common risks include:

- Inconsistent link sizing or spacing

- Weak solder joints or open links

- Clasps failing under normal wear

- Poor plating adhesion leading to discoloration

- Color mismatch across batches

- Suppliers prioritizing speed over tolerance control

Reliable components require disciplined manufacturing and QC, not just low pricing.

How Sourcify Supports Chains & Components Manufacturing

Sourcify helps brands source components that integrate cleanly into finished products.

We support this category by:

- Matching you with component-focused manufacturers experienced in chains and findings

- Vetting suppliers for tolerance control and plating reliability

- Managing sampling and fit testing

- Aligning MOQs with broader product launches

- Ensuring finish consistency across reorders

- Planning backup suppliers to reduce dependency risk

Our focus is on components that perform consistently, not just look correct at first glance.

Who This Is Best For

Chains and components sourcing through Sourcify is a strong fit for:

- Jewelry brands building modular or multi-SKU collections

- Teams scaling production volume

- Brands experiencing fit or durability issues

- Founders seeking consistency across repeat orders

- Companies assembling products across multiple factories

Ready to Get Started?

If you’re sourcing chains, findings, or jewelry components and want reliability from the start, we can help.