Built for precision, durability, and scale — not just aesthetics.

Metal jewelry manufacturing requires tight tolerances, reliable processes, and suppliers who understand both design intent and production reality. From casting to machining to hand-finishing, the way metal jewelry is made directly impacts quality, cost, and consistency at scale.

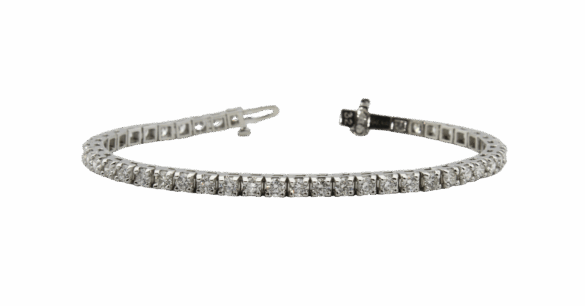

What Falls Under Metal Jewelry Manufacturing

This category includes solid and plated metal jewelry produced through casting, machining, and fabrication processes.

Common product types include:

Materials typically include brass, sterling silver, stainless steel, zinc alloys, and other base or precious metal blends depending on design and price point.

How Metal Jewelry Is Manufactured

While designs may vary, most metal jewelry follows a structured production flow:

Design & CAD Development

Digital files are created to define dimensions, tolerances, and structural details.

Mold Creation or CNC Programming

Depending on the design, factories produce molds for casting or program CNC machines for fabrication.

Casting, Machining, or Forming

Metal parts are cast, cut, or shaped according to design specifications.

Assembly & Stone Setting

Components are assembled, and any stones or inserts are securely set.

Finishing & Surface Treatment

Polishing, brushing, plating, or coating is applied to achieve the final look and durability.

Quality Control & Inspection

Parts are checked for consistency, weight, fit, and surface quality before packing.

Each step introduces tradeoffs between cost, speed, and finish quality — which is why supplier selection matters.

Key Manufacturing Decisions Founders Need to Make

Metal jewelry isn’t one-size-fits-all. Early decisions affect everything downstream.

Material choice affects cost, weight, durability, and long-term wear.

Early decisions here influence plating performance, comfort, and price per unit.

Casting allows for organic shapes and fine detail, while CNC machining offers tighter tolerances and repeatability.

The right choice depends on design complexity and production volume.

Solid construction increases weight and durability.

Hollow designs reduce material cost and weight but require tighter quality control.

Loose tolerances allow faster production and easier assembly.

Tight tolerances improve fit and consistency but increase cost and lead time.

Plating thickness, surface prep, and coating type impact durability and appearance.

Not all finishes perform equally across materials.

Lower MOQs provide flexibility but raise unit costs.

Higher MOQs reduce per-unit pricing but increase inventory risk.

Understanding these variables upfront helps avoid redesigns, delays, and unexpected cost increases.

Common Challenges in Metal Jewelry Production

This category often runs into issues when factories oversell capability or founders underestimate complexity.

Common risks include:

- Inconsistent weights or dimensions across batches

- Surface defects from poor finishing

- Weak solder points or joins

- Inaccurate tolerances affecting fit

- Plating wear or discoloration over time

- Limited QC during scale-up

Most of these issues are preventable with proper vetting, clear specs, and hands-on production oversight.

How Sourcify Supports Metal Jewelry Manufacturing

Sourcify works as your sourcing and production partner — not a directory or broker.

For metal jewelry, we support brands by:

- Matching you with vetted metal jewelry factories based on your design, volume, and budget

- Reviewing designs for manufacturability and cost efficiency

- Managing sampling, revisions, and production timelines

- Guiding MOQ, pricing, and margin decisions

- Ensuring QC standards align with your product’s complexity

- Building backup supplier options to reduce risk

Our role is to help you make informed decisions — and avoid surprises once production starts.

Who This Is Best For

Metal jewelry manufacturing through Sourcify is a strong fit for:

- Brands launching or expanding a metal-based jewelry line

- Founders scaling from small batch to consistent production

- Teams seeking better quality control or supplier reliability

- Brands looking to improve margins without sacrificing finish quality

Ready to Get Started?

If you’re exploring metal jewelry manufacturing and want experienced guidance from day one, we’re here to help.